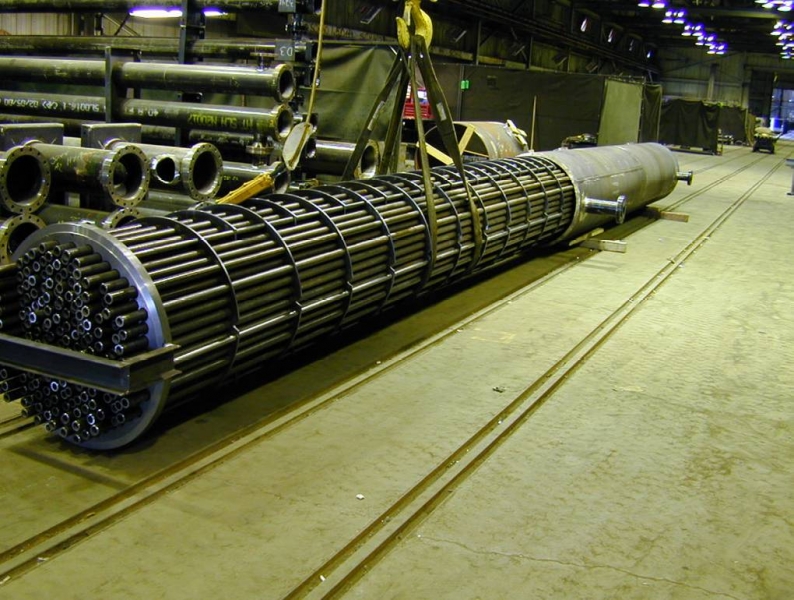

Heat Exchanger Design

Engineered Shell and Tube Heat Exchangers

Heat Exchanger Design, Inc. offers shell and tube exchangers starting at 2" IPS in all TEMA types. HED designs and fabricates to ASME code and TEMA standards. Their shell and tube line utilizes bare tube (straight and u-tubes), helical low-fin outside, longitudinal fins (inside & outside are available). These exchangers are suitable for a variety of applications and are offered in fixed tube sheets or removable bundles. The surface area ranges from (1) square foot to 40,000 square feet. Pressure range is from full vacuum to over 14,000 PSI (limited by size, material and design condition).

-

Type "U" – U-Tube Exchangers: These units are constructed using U shape tubes that are attached to the same tubesheet. This design may be used with "A", "B", "C", "N", or "D" type front end. This type is recommended for clean process fluids and those subject to chemical removal.

- Type "L", "M", and "N" – Fixed tubesheets: These units are constructed with the tubesheets integral with the shell. They may be used with "A", "B", or "N" type front head. These type units are recommended for low and high pressure, and low fouling fluids

- Type "W" – Externally sealed tubesheets: The shell side and tubeside streams are individually sealed by individual packing and are separated by a lantern ring. This is the lowest cost of the floating head designs and can be used with type "A", "B", or "C" front head. These units are recommended for low pressure, low temperature and non-hazardous fluids.

- Type "P" – outside packed floating head: A skirt attached to the floating tubesheet passes through the back end of the shell. The space between the skirt and the shell is sealed by several layers of packing and packing gland.Type "P" is recommended for low pressure, low temperature non-hazardous fluids.

- Type "T" – pull through floating heads: The floating tubesheet is designed with a larger diameter than required for the tube array.

- Type "S" – Inside split backing ring: The floating tubesheet is sealed to a floating head cover using a split backing ring and a gasketed surface. Type "S" is recommended for high pressure, non-hazardous process fluids.

Contact us for more information regarding Heat Exchanger Design, Inc. and their products:

Email: sales@southgateprocess.com

Phone: (770) 345-0010