Temptek, Inc.

Our standardized production techniques, industry recognized reliable components, and mechanically simple designs, enable Temptek to pass the savings on to the customer.

Our product philosophy is to provide you with economically affordable equipment, built for round the clock operations, providing years of trouble-free service, offering users maximum returns on their capital investments.

Temptek offers many types of auxiliary equipment such as: Tempature control units, Portable water chillers, Central water chillers, Pump tank stations, Cooling tower cells, Desiccant dryers, Vacuum Loaders, and Press side granulators. For more information on Temptek and their products please see below or contact us by phone (770) 345-0010 or email: sales@southgatepe.com

Temptek General Brochure

Portable Water Chillers:

Supply temperatures between 20° to 70°F from ¼ to 40 tons.

Air-Cooled units use ambient air to dissipate process heat.

CF Series- Air-Cooled

• 1/4 - 1.5 Tons Capacity

• Microprocessor Control

• Air-Cooled Condenser

• Galvanized Steel Frame

• Nonferrous Coolant Circuit

• Non Ozone Depleting Refrigerants

CF-A Series- Air-Cooled

• 5 to 30 Tons Capacity

• Microprocessor Based Chiller Control

• Air-Cooled Condenser

• Steel Frame and Lift Off Cabinetry

• Scroll Compresser

• Brazed Plate Evaporator

• Non Ozone Depleting Refrigerants

CF-ARC Series- Air-Cooled Unit with Remote Condenser

• 5 to 40 Tons Capacity

• Microprocessor Based Chiller Control

• Remote Air-Cooled Condenser

• Steel Frame and Lift Off Cabinetry

• Scroll Compresser

• Brazed Plate Evaporator

• Non Ozone Depleting Refrigerants

Water-Cooled units (use plant water supplies to dissipate process heat) or Air-Cooled units.

CF Series- Air & Water Cooled

• 2 to 3 Tons Capacity

• Microprocessor Based Chiller Control

• Single Refrigerant Zone

• Steel Frame and Cabinetry

• Hermetric Compresser

• Brazed Plate Evaporator

• Non Ozone Depleting Refrigerants

CF-D Series- Air & Water Cooled

• 5 to 15 Tons Capacity

• Digital Scroll Compresser Technology

• 20°F - 80°F Fluid Temperatures

• R410 Non Ozone Depleting Refrigerant

• Steel Frame and Lift Off Cabinetry

• Stainless Steel Brazed Plate Evaporator

Central Water Chillers:

Supply temperatures between 20° to 70°F from 5 to 180 tons.

Air-Cooled units use ambient air to dissipate process heat.

MA Series- Air- Cooled

• 5 to 30 Tons Capacity

• Scroll Compresser

• Air-Cooled Condenser

• Non Ozone Depleting Refrigerants

• Brazed Plate Evaporator

TTOACS Series- Air- Cooled

• Designed for Outdoor Installation

• Single or Multiple Refrigeration Zones

• Microprocessor Control Instrument

• 5 to 130 Tons Capacity

• Integral Air-Cooled Condenser

• Fluid Temperatures of 20° to 70°F

Water-Cooled units use plant water supplies to dissipate process heat.

MW Series- Water-Cooled

• Scroll Compressor Up To 30 Tons

• Brazed Plate Evaporator

• Non Ozone Depleting Refrigerants

• 5 to 40 Tons Capacity

• Water-Cooled Condenser

• Process Temperatures of 20° to 65°F

MW Series- Water-Cooled

• Multiple Refrigeration Zones

• Microprocessor Control

• Non Ozone Depleting Refrigerants

• 5 to 180 Tons Capacity

• Water-Cooled Condenser

• Galvanized Steel Frame

• NEMA 12 Electrical Cabinet

Water-Cooled units (use plant water supplies to dissipate process heat) or Air-Cooled units.

TTI Series- Air & Water Cooled

• Complete Central Chiller & Pump Tank Package

• Water-Cooled & Air-Cooled Models

• Process Temperatures of 20° to 70°F

• 20 to 280 Tons Capacity

• Uses Non Ozone Depleting Refrigerants

• For Indoor Installation

• Multiple Refrigeration Zones

• Pump Distribution System

Temperature Control Units:

Water Units circulate water for process temperatures from 30° to 250°F

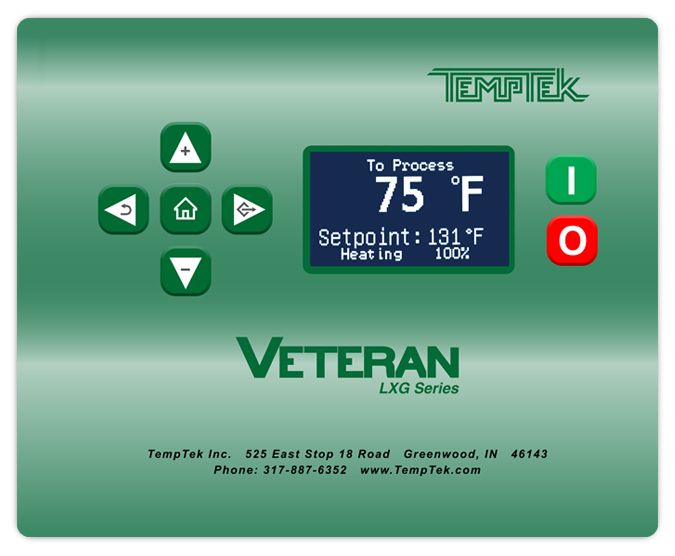

VT Series- Water Unit with LXG Series Control Instrument

|

• Stainless Steel Cabinetry • LXG Series Control Instrument • Modulating Cooling Valve • Operating Trmperature to 250°F • Heaters to 34 KW and Pumps to 7.5 HP |

VT Series- Water Unit with LXT Series Control Instrument

|

• Stainless Steel Cabinetry

• LXT Series Control Instrument

• Modulating Cooling Valve

• Operating Trmperature to 250°F

• Heaters to 34 KW and Pumps to 7.5 HP

|

VT Series- Water Unit with LS Series Controller

|

• Stainless Steel Cabinetry • LS Series Control Instrument • Solenoid Cooling Valve • Operating Trmperature to 250°F • Heaters to 16 KW and Pumps to 3 HP • Custom Cast Pump & Tank Assembley |

VT Series- Water Unit with LX Series Controller

• Stainless Steel Cabinetry

• LX Control Instrument

• Modulating Cooling Valve

• Operating Trmperature to 250°F

• Heaters to 16 KW and Pumps to 3 HP

• Custom Cast Pump & Tank Assembley

VT Series- Water Unit with 300°F Series Controller

• Stainless Steel Cabinetry

• 300°F Control Instrument

• Solenoid Cooling Valve

• Operating Temperature to 300°F

• Heaters to 34 KW and Pumps to 7.5 HP

• Custom Cast Pump & Tank Assembley

Oil Units circulate oil for process temperatures from 100° to 400°F.

VTO Series- Oil Units

|

• Microprocessor Control • 1 - 3 HP Centrifugal Pumps • Solenoid Cooling Valve • Process Temperature to 400°F • 12 - 24 KW Heaters • Cooling via Heat Exchanger Option • In Stock or Short Lead-time |

Pump Tank Stations:

Polyethylene units use a polyethylene reservoir.

Mild Steel Units use a mild steel reservoir.

PPT Series- Polyethylene

• Capacities From 450 - 3000 Gallons

• Tower or Chilled Water Systems

• Pumps from 2 - 60 HP

• Flows from 40 - 1250 GPM

• Seamless Rotational Molded Reservoir

• 10 Year Tank Warranty

PT Series- Mild Steel

• Capacities From 250 - 300 Gallons

• Tower or Chilled Water Systems

• Pumps from 2 - 60 HP

• Flows from 40 - 1250 GPM

• 7 ga Steel Reservoir

• Mild or Stainless Steel

Cooling Towers:

Provide cooling water through evaporation and offered in capacities from 20 to 540 tons.

• CTI Certified Peformance

•â€‹ Compact Space Efficent Design

• 45 to 540 Tons Capacity

• UV Stabilized Fiberglass Shell

• TEFC Fan Motor with ABS Fan Blades

• 10 Year Shell Warranty

• 5 Year Mechanical Warranty

Granulators, Desiccnt Dryers, Vacuum Loaders:

Granulators provide precision scissor cut action providing maximum through-put efficiency.

Continuous duty desiccant dryers are designed to supply an uninterrupted flow of low dew point air.

Vacuum Loaders are compact for small throughput applications.

Email: sales@southgatepe.com

Phone: (770) 345-0010